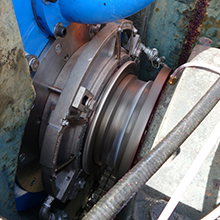

A customer was experiencing frequent gland failures on an Xstrata UFG 5000 Isa Mill™. Although it was a slow turning mill and low pressure, it was difficult to maintain a suitable seal with conventional gland packing. This was an acute and chronic maintenance event, impacting and causing a bottleneck in production of the plant, representing an annual downtime of more than 85 hours.

on an Xstrata UFG 5000 Isa Mill™. Although it was a slow turning mill and low pressure, it was difficult to maintain a suitable seal with conventional gland packing. This was an acute and chronic maintenance event, impacting and causing a bottleneck in production of the plant, representing an annual downtime of more than 85 hours.

A review was undertaken of similar failure mode s affecting pumps throughout the mill which was followed by close liaison with PUMPNSEAL Australia to engineer a suitable mechanical seal solution. Based on the earlier success of operating Chesterton Split seals in slurry pumps in higher head applications it was considered worth a trial. A 360mm standard version of the 442 seal was installed when the mill was scheduled for regular maintenance. The initial installation which took 2 hours eventually resulted in the elimination of further seal and bearing failures due to water contamination.

s affecting pumps throughout the mill which was followed by close liaison with PUMPNSEAL Australia to engineer a suitable mechanical seal solution. Based on the earlier success of operating Chesterton Split seals in slurry pumps in higher head applications it was considered worth a trial. A 360mm standard version of the 442 seal was installed when the mill was scheduled for regular maintenance. The initial installation which took 2 hours eventually resulted in the elimination of further seal and bearing failures due to water contamination.

Features and Benefits of using Chesterton 442 Mechanical Seals:

- No Failures. Seal failures reduced to zero

- Planned 18-month maintenance program to inspect mechanical seal

- Reduced gland water usage

- Increased availability has provided an additional 1600oz of gold per annum

- A sustainable unit cost saving of $2.56/oz directly in the bottleneck (revenue stream)

.Click here to find out more about the Chesterton 442 Mechanical Seal