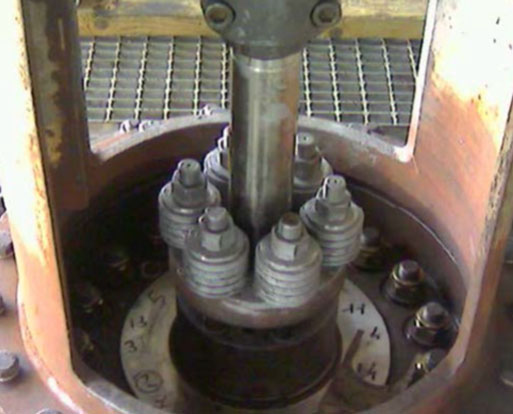

The previous sealing system was made out of an old Chesterton 5600+5300 set as following:

- 3 x 5300 rings + 2 x 5600 rings in the bottom of the stuffing box

- Lantern ring

- Back-up set consisting of 1 x 5300 sealing ring + 2 x 5600 rings

This sealing system was failing every 2-6 months. There were some OEM springs installed on the studs.

The Customer asked Chesterton for immediate support in February 2008. He agreed with the Complete Live Loading solution with carbon bushing, three 5300 sealing rings and three to four 1600 end rings, with 6 Live Loading assemblies for 24 mm studs. The first two valves are packed in April 2008.

By the end of 2008, none failed and the customer standardized all the eight critical valves. In 2013 the valves are still running leak free.

Products used in this solution: Valve Liveloading 5150, Die Formed ring 5300, 1600

- Chesterton can extend the MTBR on severe service valves with their proven sealing systems.

- Chesterton Valve Live Loading is designed to reduce leakage and extend the life time of the valve.

- Chesterton guarantees that valves stay leak free for a period of at least 5 years with their valve live loading systems

ROI

Previous solution (OEM Solution)

Total Cost (every 3 months): 2.800 € + production loss

Chesterton Solution:

Chesterton Live Loading: 3.500 € NO Production Loss

Total Cost (20 months): 3.500 €

Total for eight (8) valves: 128.800 € + production

Application/Equipment:

- Main Heater

- Quantity 8 Valves

- Stem diametre 70mm

- M24x6 Studs

- Medium steam was outputting at Temperature: +450°C (300 bar)