In the refining section of fibre board manufacturing, several screw feeding presses such as the moistening screw, plug screw feeder, pre-heater discharge screws and the refiner infeed screw, are used for conveying the chips through the process.

The sealing of these screws is often done through a standard stuffing box arrangement with compression packing. This sealing arrangement often suffers from short packing life that result in steam leakages.

These steam leakages present a safety issue and cause subsequent failure of the bearings because of moisture.

Mechanical seals are usually considered as the solution to the packing problems of the feeding screws. But as these screws are difficult and time consuming to disassemble, standard mechanical seals are not a practical solution for mills.

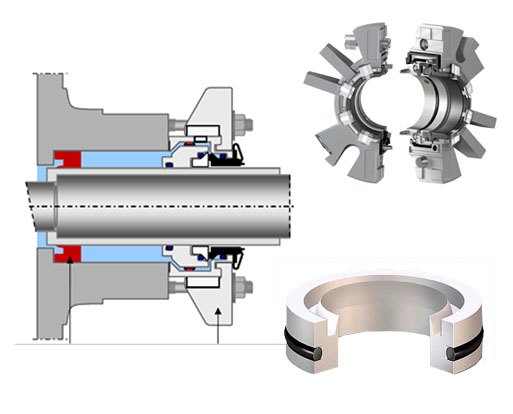

Chesterton innovative split mechanical seals provide the sealing performance of mechanical seal while avoiding costly downtime of the equipment. Installation and repair can be done quick and easy on site.

The 14K split flexible lip restriction bushing installed with the split seal, protects the seal from abrasion from chips and fibers allowing optimal sealing performance and longest time between repairs.

- Reduced maintenance costs

- Improved reliability

- Easy and quick to repair

- No equipment teardown

- No gland adjustments

- Safer working environment